All of the information below, such as technical industry terminology, is cited from the Mazak website, and there are links that will take you to each machine section and the list of their different models.

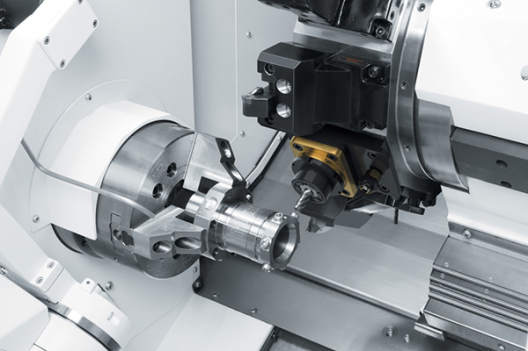

Multi-Tasking

Multi-Tasking machines allow for several machining steps all at once within DONE IN ONE® processing. In Mazak's own words: "With the industry’s most expansive product range, Mazak Multi-Tasking machine configurations can pack second turning spindles, multiple tool turrets with rotary tool stations, Y-axis off-centerline capability, tilt/rotary B-axis milling spindles, rotary/tilt tables and large capacity tool magazines."

Vertical Machining Centers

When metal needs to be removed from a part, vertical machining comes into play by removing it. The spindle is vertical so the tool is oriented the same way and able to cut across the top of a part.

Turning Centers

Utilize a lathe with a CNC control to make cylindrical parts in a straight movement. Complete with MAZATROL programming language, you can use either G-code programming, conversational programming, or both.

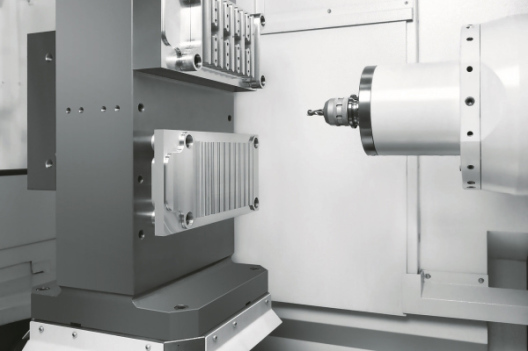

Horizontal Machining

Like vertical machining, horizontal (milling) sets a part level with the ground below the machine to remove metal from its surface. It not only cuts down on part cycle times, but its “two pallet changer integration” allows for operations without needed supervision.

5-Axis Machines

5 Axis Machines work with not only the X, Y, and Z axes, but A and B as well. This allows for more dynamic, multi-dimensional part creation and less time spent setting up fixture preparation.

HYBRID Multi-Tasking

Mazak HYBRID Multi-Tasking machines incorporate technologies for additive manufacturing or joining as well as DONE IN ONE® gear manufacturing through Mazak’s SMOOTH Gear Cutting. Additive technologies include laser and multi-laser metal deposition, along with wire arc AM, while joining techniques include Friction Stir Welding (FSW).

PALLETECH

Exclusive to Mazak, PELLETECH brings together multiple manufacturing stations into a cell and utilizes software that can see various stages of part processing. If needed, a process can be paused or stopped to change course of machining at zero expense or penalty.